Conceptual insulation box

All houses are insulated…why is this one special?

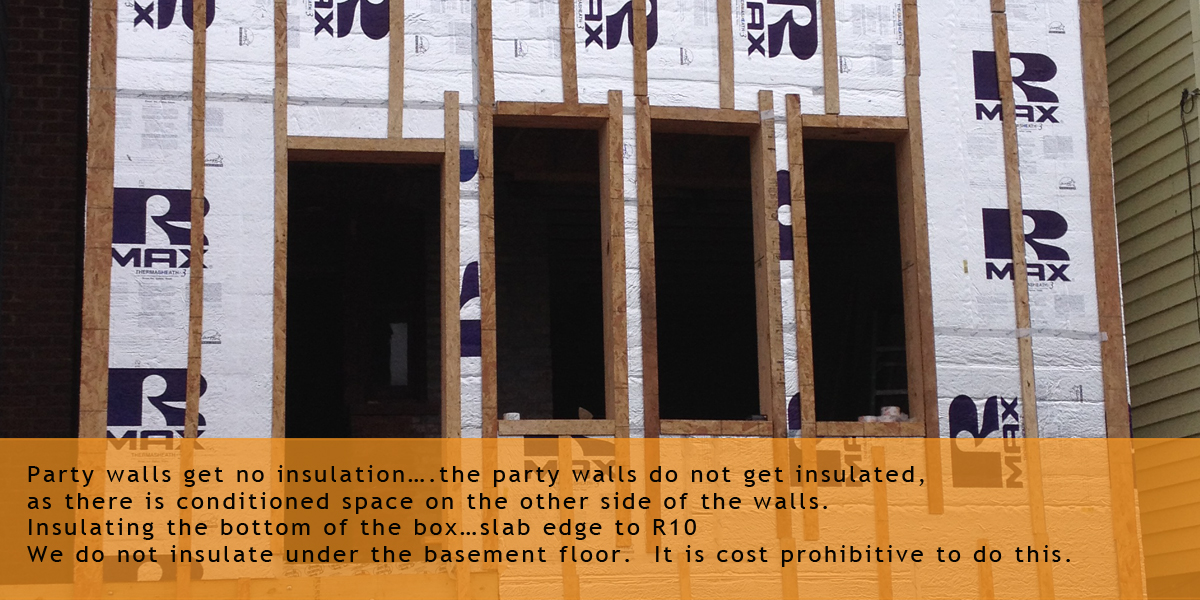

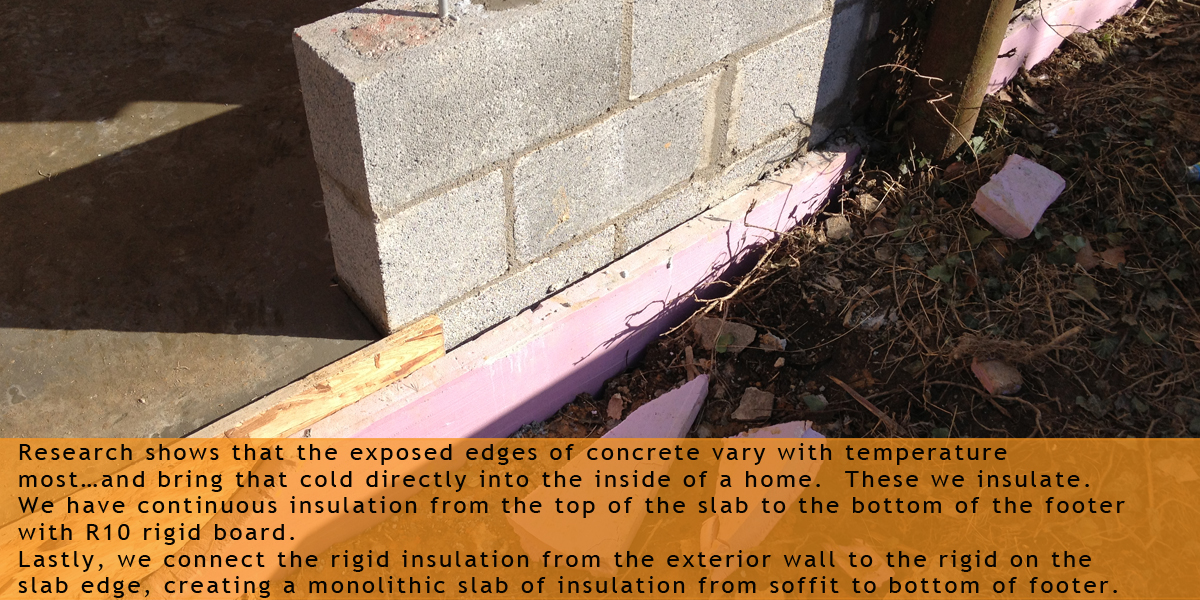

Think of the house as a box…the box has a top, four sides and a bottom. The best insulation strategy is to not only insulate all six sides of that box but connect all the seams of the insulation to make the insulation continuous. That is the ideal. We strive to get as close to this ideal as possible.

Thermal bridging

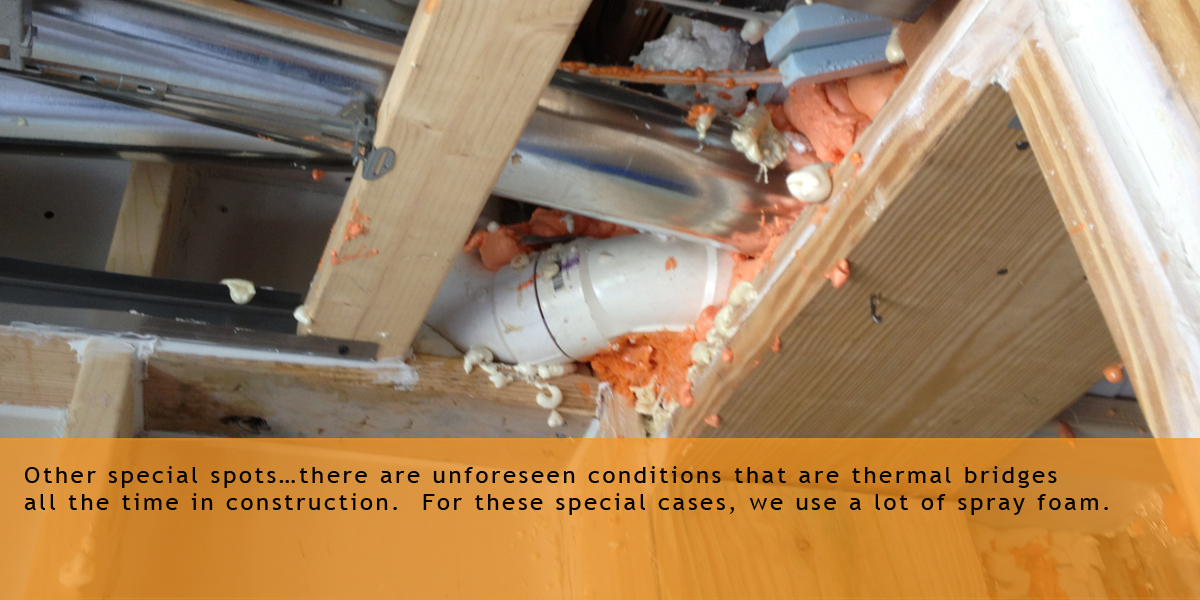

The other concept that drives the design choices we make in the building skin is trying to eliminate thermal bridging.

We all know that heat and cold can travel through materials. In homes, for example, heat and cold travels from the outside to the exterior sheathing, which is directly connected to the studs, and the studs transmit the heat or the cold to the inside of a home creating a “thermal bridge” from the exterior to the interior of the home…raising heating and cooling bills.

This image shows thermal bridging in action with a conceptual image from an infrared camera. The yellow studs show more heat loss than the green and blue insulated stud bays.

Where and what kind of insulation is used can interrupt this flow of heat and cold, and eliminate the thermal bridging as much as possible. Eliminating thermal bridging drops the energy used by a home…and just as importantly makes a home more comfortable.

Insulating the top of the box to R60

It’s a row home, so we are nearly a perfect box to begin with, so that’s in our favor. We simplify the “top” of our box to be the second floor ceiling. We blow in cellulose insulation to R60.

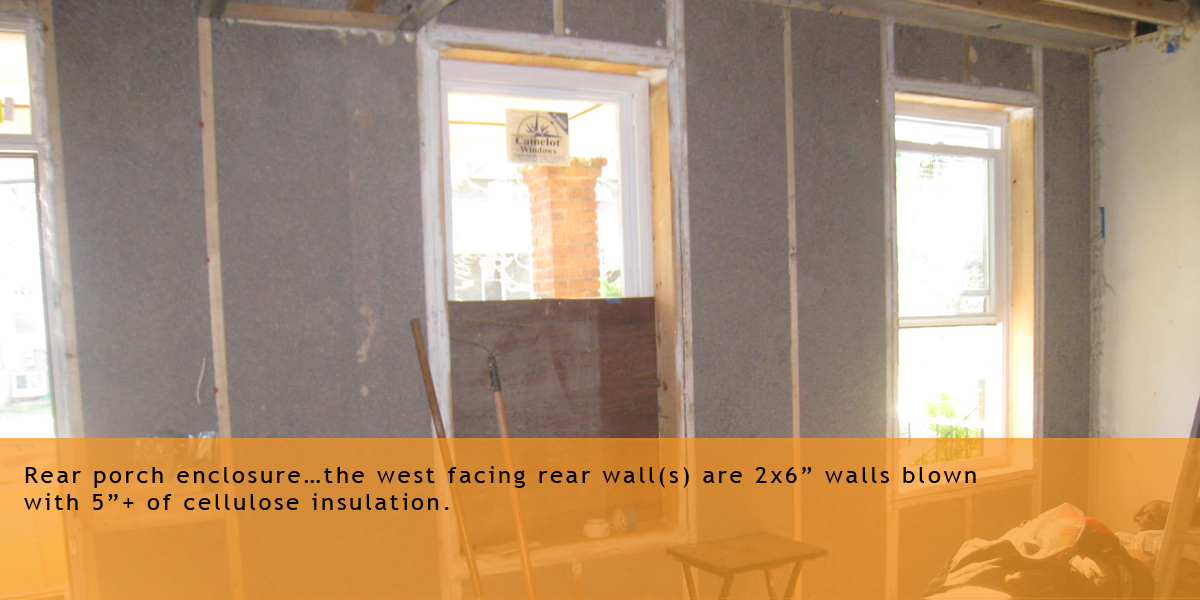

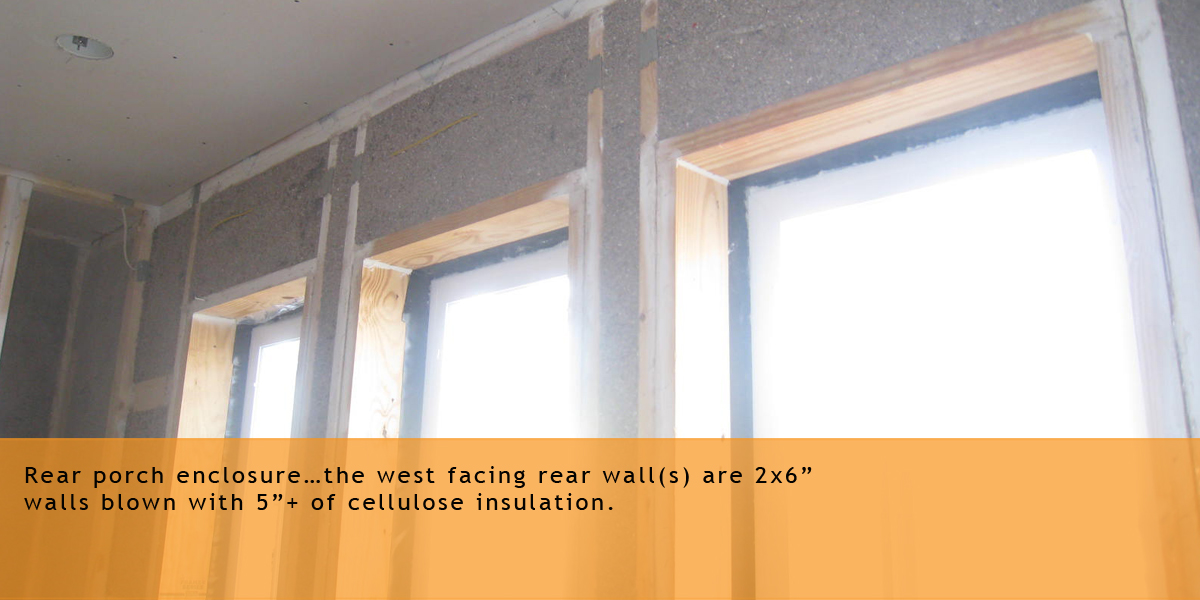

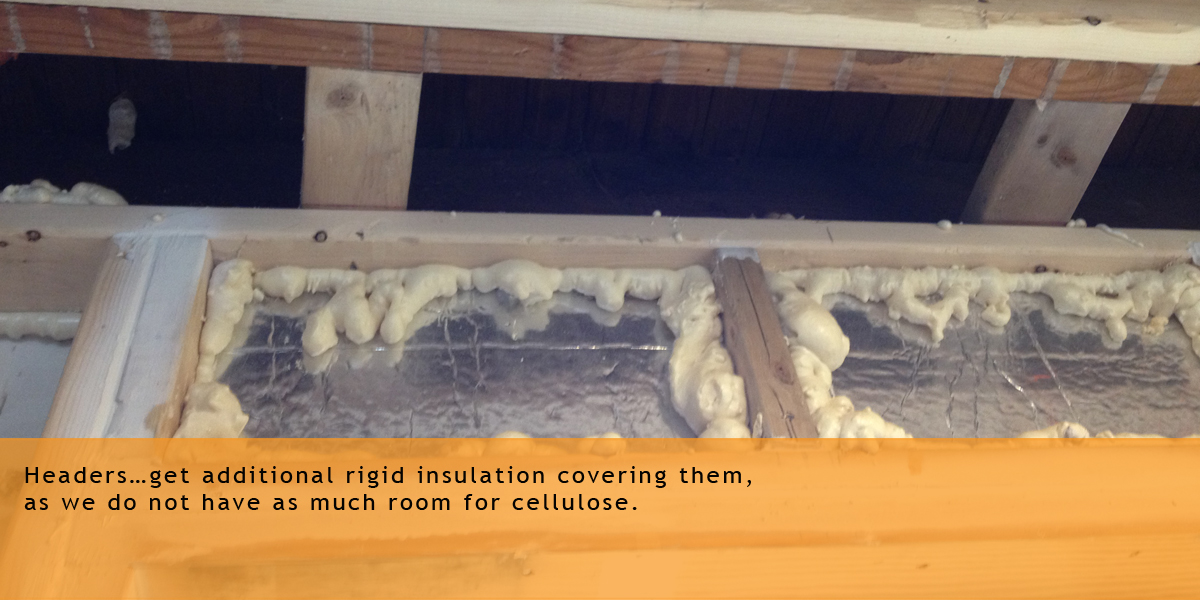

Insulating the sides of the box to R25-35

Front wall…the east facing front wall is the existing brick face of the home with plaster directly on the brick for an interior finish. This is a massive amount of thermal bridging. We build a stud wall on the interior of the room with a gap to the plaster. The gap disconnects the thermal bridge. We then blow in ~4-5” of cellulose into the cavity and the gap.